NDT--- What distinguishes us

Our team consists of a total of 5 experienced auditors.

We are neither location-bound nor otherwise limited in terms of deployment, so that we are also able to react flexibly and can also carry out longer-term foreign assignments, etc

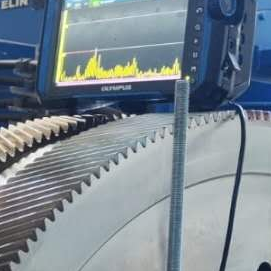

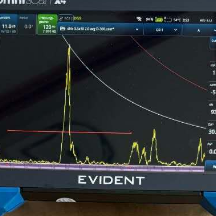

We test with the latest test equipment

Examples of our services, which we also offer in addition to the standardized exams-Ultrasonic Tooth Volume Testing,

- UT/PA which can also be used to make microstructures visible - Magnetic particle inspection of tooth flanks, etc. - Dye penetrant inspection (red/white and fluorescent possible) on white metal bearings - Ultrasonic bond inspection on white metal bearings

UT level 2

Ultraschallprüfung

Ultrasonic testing is a technique used to detect flaws in materials such as metal without causing damage. As a volumetric method, UT is employed to ensure that materials and products do not exhibit internal material inconsistencies. This allows us to clearly determine the size, extent, and depth of the flaw..

MT Level 3

Magnetpowder Testing

Magnetic powder testing allows us to detect defects/imperfections in ferromagnetic materials. Open defects on the surface and even closed defects just below the surface can be found. This method enables the rapid detection of cracks, pores and other irregularities. A quick and effective way to ensure the quality of metal components.

PT Level 3

Dye Penetrant Testing

Dye penetrant testing identifies even the smallest surface defects such as cracks and pores in materials with high accuracy. This method is used across all common industries, including metal processing, aerospace, automotive manufacturing, and nuclear power. We primarily use this to make surface-open imperfections/defects visible.

VT Level 3

Visual Inspection

Visual inspection is usually carried out before other methods in various parts. It is done with the naked eye or with aids such as a magnifying glass, borescope, hand mirror, video endoscope, etc. The dimensions are also checked.

ISO 9712 - Stufe 3

ServiceT

Level 3

•Preparation of test instructions & procedure descriptions

• Acceptances on behalf of the customer

• Neutral (independent)control of test reports

• External audit and supervision